What is Inventory Visibility?

What do we mean by inventory visibility? Most businesses are only concerned with quantities and products and don’t pay much attention to where products are located. The number of inventory locations varies based on the size of the business and its operations. Even little bins and drawers, as well as vehicles, can be locations. Therefore it’s critical to look after them in the same way that we look after storage rooms, pallets, and aisles to obtain accurate inventory data.

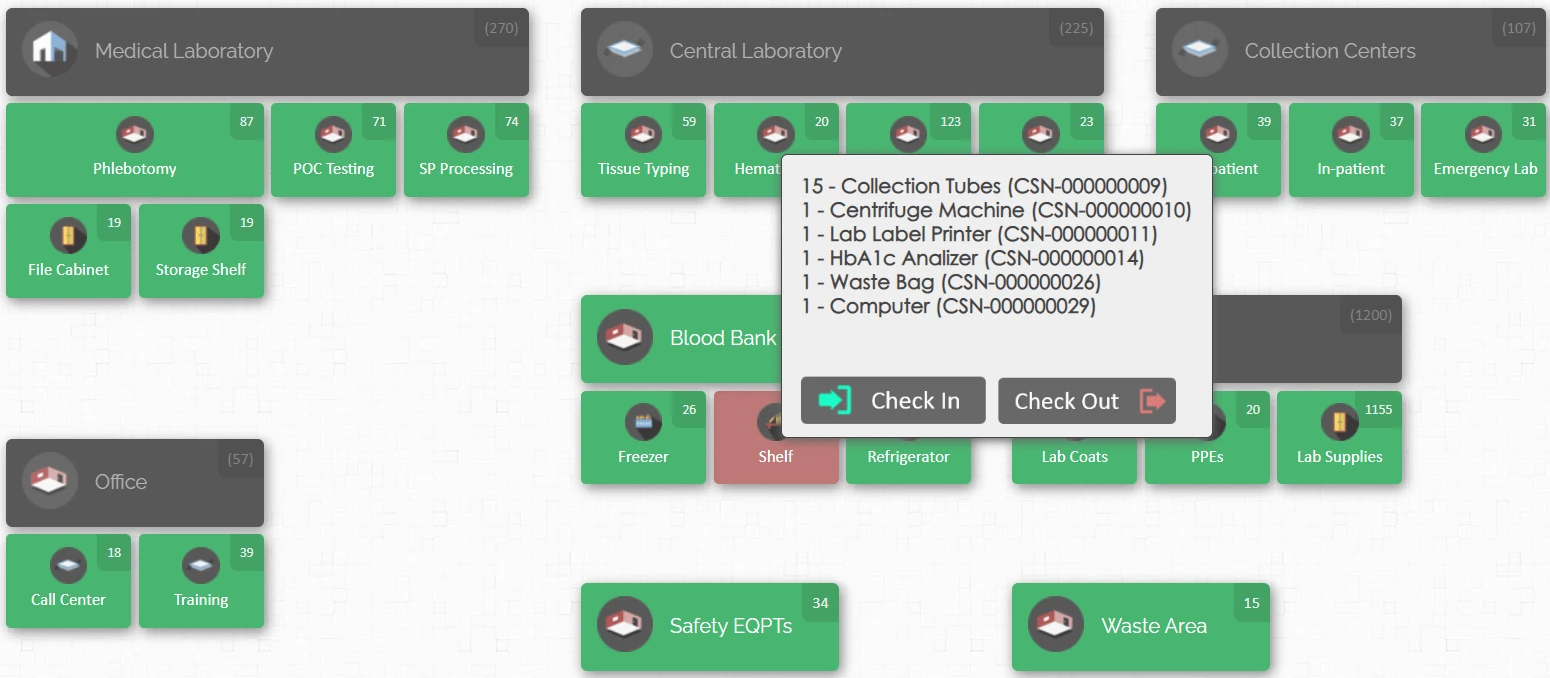

True inventory visibility goes beyond knowing how many you have, it also includes knowing where each item is at any given time. This is extremely important, especially for organizations with multiple locations and goods.

The ability to track inventory movement across multiple locations and different phases of the business process allows for better inventory management.

How do you achieve inventory accuracy and inventory visibility?

The traditional methods of inventory tracking, like excel sheets and paper documentation cannot provide both accuracy and inventory visibility. These are also prone to human error.

Accuracy begins when products arrive at the dock and continues until they are placed in stock. Products may travel through several procedures, and if you don’t have the correct inventory management system in place to track each one, you may lose track of the actual count and location of your inventory. Inventory visibility is not just knowing how many you have, but also keeping a precise count of everything and knowing where everything is at any given time.

A good inventory system is the best way to obtain both inventory visibility and accuracy. It’s a little investment to improve overall inventory management and avoid costly inventory management errors. There are a number of inventory management systems available, so choose one that best suits your procedures and actually addresses your inventory issues.

The Benefits of Inventory Visibility

Inventory visibility and control are both integral parts of any business operation. If your business can’t answer basic questions like how many you have and where each item is kept, you could be missing out on opportunities. From the retail management perspective, you could be losing countless sales opportunities. In a huge manufacturing plant, you could be losing money because of delays in finding spare parts for your machinery. Or, if you are in the medical field, you may even lose lives.

Better inventory visibility paves the way for:

- Accurate inventory quantities on hand

- Knowing how much inventory to purchase

- Knowing when to purchase inventory

- Having a bird's eye view and centralized inventory management

- Improved communication between management and operations

Preventing excess inventory

No organization plans to buy something only to have extra inventory but this happens all the time, and the available inventory data triggered that decision.

How would you know what you have if you don’t even have access to real-time information on how many you have and on where each item is located? It’s not always easy to determine when your company’s excess inventory will become a problem. However, a lack of visibility into your inventory is one of the most common causes of goods stacking up in your warehouses. Fear of running out of stock will cause you to order more than you need to avoid stockouts.

If the buffer inventory doesn’t meet demand, you’ll end up with excess inventory, and your hard-earned money will sit in your warehouse. This is risky too, especially in retail where trendy items almost change every month.

By improving inventory visibility, you can get the data you need to develop more accurate forecasts. Having more confidence in your current inventory levels also minimizes the need for always having a buffer inventory, which is a major cause of excess inventory.

Preventing stockouts

This is one of the most common issues that every company may face. Without a warehouse management system, inaccurate inventory counts can lead to stockouts.

While retailers may be able to give customers alternative brands of products, this may still result in a terrible customer experience. In other industries, such as manufacturing plants or healthcare this might not be possible because each item serves a specific purpose.

Your business can avoid stockouts by committing to enhancing inventory visibility. Stockouts hurt not only profitability but also the image of your business.

Better business decision-making

It’s far easier for inventory managers and retail associates to look into the system than roam around the store or warehouse and comb through every pallet and box.

A good inventory management software includes a system that works like a bird’s eye view that allows you to manage day-to-day operations. Using a computer or mobile device, you may quickly filter out product information, inventory levels, location, and other critical details like price, expiration dates, barcodes, and other identifiers.

Another advantage of the inventory management system is having features that help decision-making. When trying to keep everything in sync between offices, warehouses, or retail, there are several factors to consider. Management gets easier when everyone is looking at the same thing. There will be no inconsistencies between the opinions of different people on the inventory numbers. Everyone in the firm has access to the same information and can make data-driven decisions for the business.